Screen Printing Consultation

Screen printing is a process where ink is pushed through a screen onto fabric. This process is commonly used in the production of accessories made from silk, cotton, viscose, and other materials. Accessories such as scarves, bags, or t-shirts are printed with individual designs.

Screen printing is particularly effective when using lightweight materials such as silk or viscose. These materials can be more difficult to print with other techniques such as digital or offset printing. However, screen printing is also suitable for heavier materials such as cotton and polyester.

The process of screen printing begins with the design being printed onto a transparent film. Then, a stencil is made from a fine mesh screen that precisely replicates the design. The stencil is then placed onto the fabric and the ink is printed through the screen. The ink is directly applied to the fabric through the printing process, resulting in a durable and high-quality outcome.

Screen printing is often used to print individual designs on accessories such as t-shirts, bags, scarves, and other clothing items. Different colors and effects can be used to achieve a unique look. Since screen printing is a manual process, it is particularly suitable for small print runs or individual pieces.

Overall, screen printing is a popular and effective method for printing accessories made of silk, cotton, viscose, and other materials. With this process, individual designs can be created on high-quality fabrics, resulting in unique and durable accessories.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDigital Printing Consultation

Digital printing is an advanced printing technology that allows designs to be printed directly from a computer onto various materials such as silk, cotton, viscose, and other fabrics. Unlike traditional printing methods such as screen printing and transfer printing, which are limited to certain materials and offer a limited color selection, digital printing allows for a wide range of colors and designs that can be printed precisely and in detail on almost any material.

Accessories such as scarves, bags, ties, handkerchiefs, and other fashion items are often printed using digital printing technology. This is because it offers high flexibility to print individual designs on the fabric, enabling unique and personalized accessories. Digital printing technology is also very effective when it comes to printing patterns with many colors, shades, and complex designs that may be difficult with other methods.

Digital printing on silk is particularly popular because it is a very lightweight and fine material that lies gently on the skin and allows for high quality print images. Viscose and cotton are also popular materials for digital printing, as they are very absorbent and have a high color uptake, resulting in vibrant and vivid colors. Other materials, such as polyester and nylon, can also be printed with digital printing, but they often require special pre-treatment to properly fix the colors.

Digital printing is applied to accessories made of silk, cotton, viscose, and other materials to enable unique and personalized designs that are not possible with other printing technologies. Digital printing allows for precise and detailed printing of complex patterns, images, and colors on a variety of materials, providing high quality and durability of the printed image.

Pad printing consultation

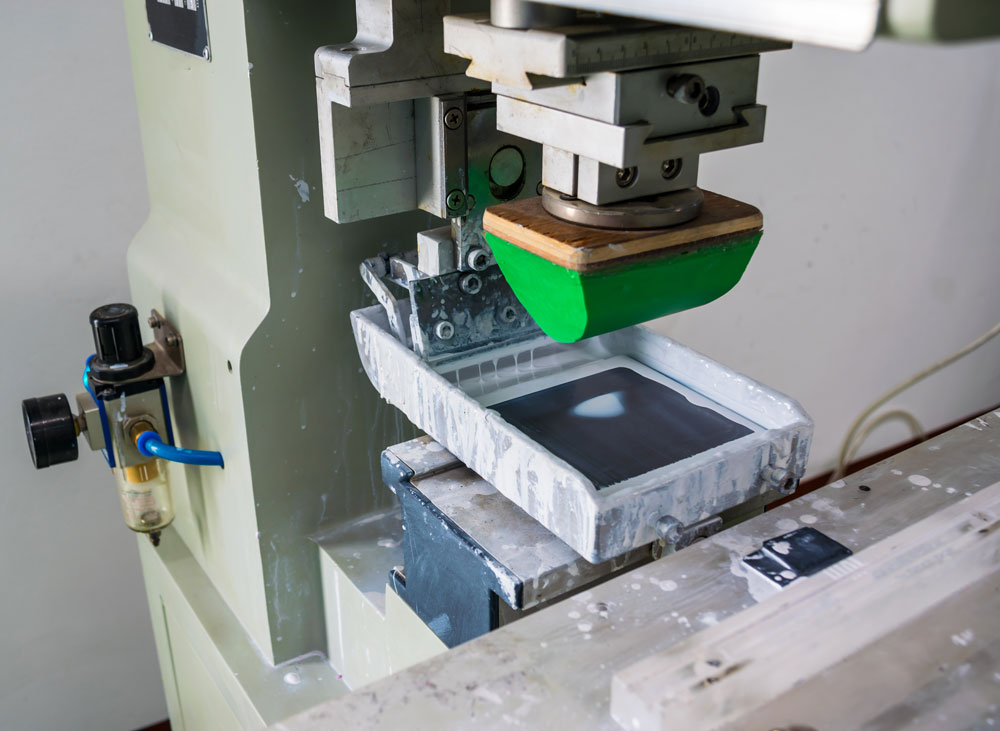

Pad printing is a method for printing surfaces that is widely used in many industries. It is an indirect printing process in which an elastic pad made of silicone or rubber is used to transfer the print image from a printing plate to the object to be printed.

Pad printing is often used for printing on uneven, curved, or irregularly shaped surfaces where other printing methods such as screen printing or digital printing technology are unable to achieve a clean and accurate print result.

The process is used in many industries, including the automotive industry, electronics industry, toy industry, advertising industry, medical and pharmaceutical industry, as well as the textile industry. It is used for a variety of applications, such as printing logos and lettering on products, labeling products, and producing stickers and labels.

Pad printing has the advantage of achieving high print quality on a variety of materials, such as plastics, metals, glass, ceramics, and textiles. Additionally, the process is also very fast and cost-effective, especially for small to medium print runs.

Overall, pad printing is a proven and versatile printing process that can serve a wide range of applications in many industries.

Printing consultation Transfer printing

Transfer printing is a method for printing on textiles, plastics, ceramics, and other materials. A print design is applied to a carrier film and then transferred to the target material through heat and pressure. Transfer printing allows for high precision and a wide range of colors, making it particularly suitable for printing images and photos.

Transfer printing is often used in the clothing industry to print T-shirts, jerseys, jackets, and other clothing items. Transfer printing is also commonly used in advertising to personalize promotional items such as pens, keychains, or mousepads. Additionally, transfer printing can be used for the production of ceramic and glass products as well as for printing on plastic parts.

One advantage of transfer printing is that it is relatively quick and easy to perform. Expensive printing plates or cylinders are not required, as is the case with other printing methods. Even for small quantities, transfer printing is economical, as the print design can simply be printed onto the carrier film and then transferred to the material.

Another advantage of transfer printing is that it is particularly durable and resilient.

But do you really want to deal with it? We'll make this decision for you as one of the leading manufacturers.